Analyzing Technical Drawings for Additive Manufacturing with Werk24

Can It Be Additive Manufactured?

Additive manufacturing (AM) has long become a valid option for end products. The industry sees the future of AM especially for small and special series, such as old components replacement.

As a manufacturer, you might want to take the ride of Additive Manufacturing, but realize that not every component is suitable for AM. You have numerous technical drawings in your archive waiting to be assessed for AM feasibility. It will take tremendous resources and time to read through all those drawings, manually predict their suitability for additive manufacturing and assess which additive technology fits the best.

Werk24’s Additive Analysis Solution

Werk24 helps you accelerate the adoption of additive manufacturing (AM) by assessing the AM feasibility of the technical drawings and suggesting the most suitable AM technology. We have developed this technology that analyse many factors on the drawing incl. Outer Dimension, Material and Tolerances to provide a highly effective AM analysis to our customers.

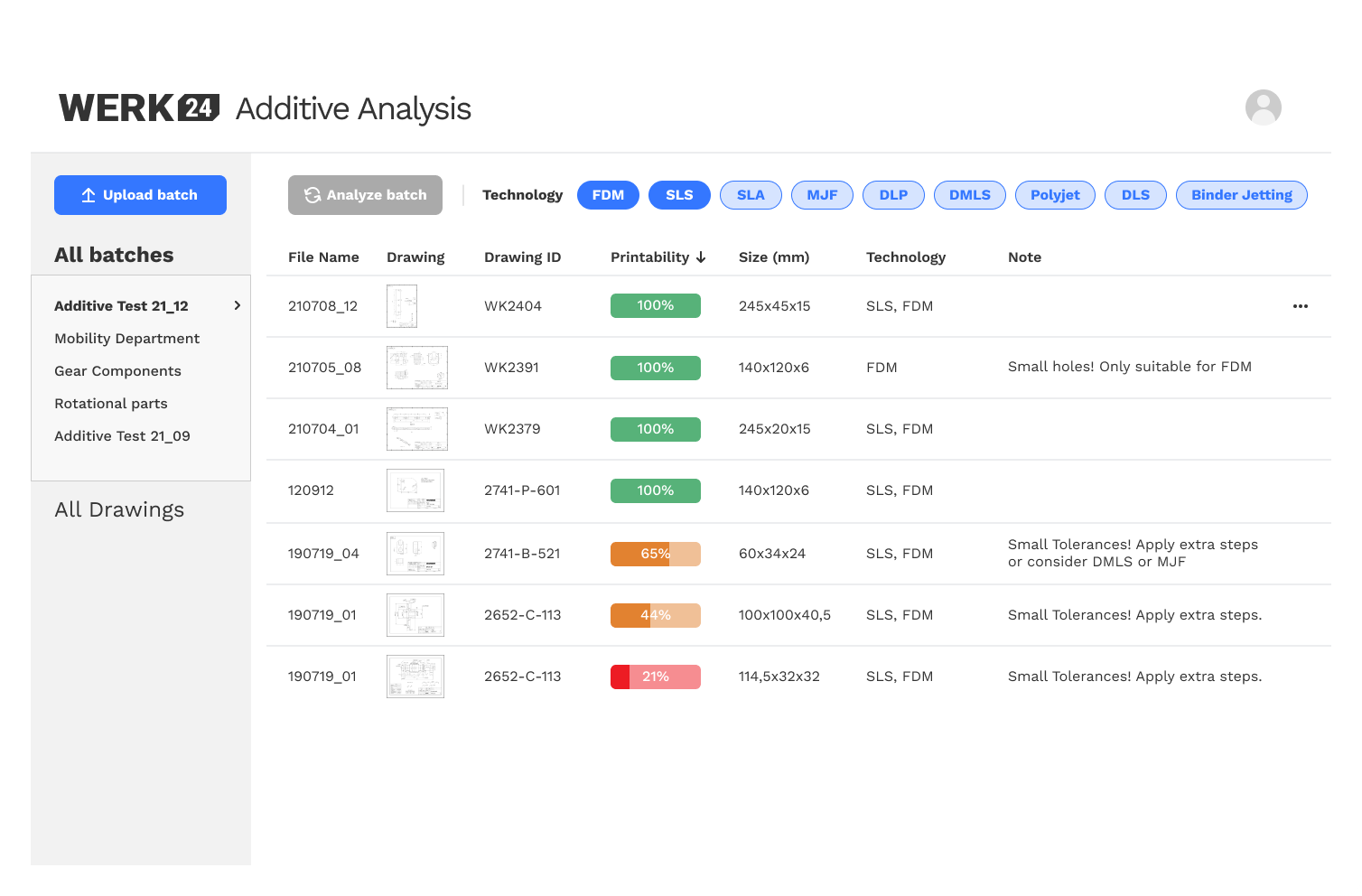

Just upload your batch of technical drawings and set the range of technologies that are relevant to you. We calculate a printability score for each drawing: 100% means it is printable with the selected technologies, while a lower score means it requires another technology or extra finishing step such as sanding, threading or drilling.

With Werk24’s Additive Analysis, you can save the resources that are otherwise spent on analysing drawings and even creating 3D models. This allows you to focus on the highly feasible parts first and easily categorize drawings for different AM machines or suppliers. And for the parts needed a closer look and further decision, you are also provided in-depth information such as the alerting elements, alternative AM technologies or further steps.

Additive Manufacturing and Challenges in Adoption

Additive manufacturing is the process of adding substances to manufacture or create an object. 3D printing is a form of it. Although many believe AM is a relatively new technology, it has been around since the late 1980s. And nowadays, AM is becoming a serious means of manufacturing, particularly in the area of metal printing. It offers a transformative approach to assembly and industrial manufacturing. Ambitious manufacturing companies looking to advance their research and development and even production turns to additive manufacturing.

However, not all components can be produced through AM. Some are technically not possible, while some might require extra sanding, threading or drilling. Currently, there are digital solutions that analyse the 3D model for AM feasibility. However, some AM constrains from technical drawings are missing for a thorough assessment, such as Tolerances, Threads, or the Material. Moreover, 3D models might not available in all situations. All this forces companies to spend considerable money and time to analyse files through manual effort, and eventually end up missing AM opportunities.

Werk24’s Answer to Additive Manufacturing

The market has searched for sophisticated and efficient solution to analyse Additive Manufacturing feasibility based on Technical Drawing. Werk24 is answering this with our newly launched product Additive Analysis. Upon request, you can upload batches of Technical Drawings and receive AM feasibility scores, suitable technologies, or in-depths notes for alternatives and extra steps.